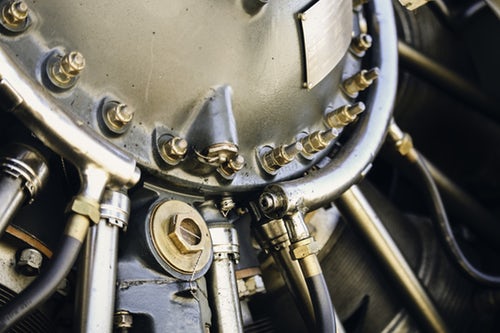

Engineering at USW has a strong portfolio of traditional engineering courses, all of which are accredited by the appropriate professional body.

This course aims to produce graduates equipped with the prerequisites to work in an Industry 4.0 manufacturing environment. This requires a balance of mechanical engineering, electrical/electronic engineering, embedded systems, cloud computing, and data analytics, focusing on the manufacturing industry.

Inclusivity is at the core of this course offering a route to HE for students who would normally shy away from a traditional university education, and ensuring graduates leave the university with excellent employability skills and knowledge. The course takes a challenge-based approach and has activity around solving real engineering problems. Therefore, to demonstrate your aptitude and ability, the assessment mode throughout the course will not include examinations.

USW Engineering has a long history of graduates who have excellent careers across the industry. Our students are aspirational, able, practical and professional graduates and the industry snap them up immediately.

What you will study

The key to Industry 4.0 is the digitisation and acquisition of actionable data from the manufacturing process, which leads to information, knowledge, insights and any other form of data-driven intelligence and analytics to improve the manufacturing process. To achieve this, the utilisation of Smart Sensors, IoTs, Cloud-Based computing and Advanced analytics allows for real-time automation of the manufacturing processes, improving efficiency, better asset utilisation and less downtime by employing predictive maintenance analytics. Students with these skills are in high demand!

Year 1

Students will be introduced to the elements involved in the mechanical and electrical/electronic design of machines/products during the first year and the essential analytical skills for working in an Industry 4.0 setting. They will learn to interface and program microcontrollers connected to sensors and actuators used in intelligent control applications. They will understand different manufacturing methods through an applied approach. They will conclude the academic year with a single project of designing and producing a simple manufacturing machine through applying the skills and knowledge attained through the taught modules.

Year 2

Students will study CAD to produce detailed technical drawing during the second year and gain the ability to apply advanced manufacturing techniques, such as CADCAM, in producing mechanical components. They will learn to design pneumatic circuits and have the knowledge and understanding of electrical installations that comply with the IET 18th Edition Wiring Regulations. They will learn to design intelligent sensors to acquire manufacturing data and communicate this to a PC for analysis and visualisation. These taught elements will feed into the 40 credit group project, which focuses on a teamwork approach in designing and developing a manufacturing machine.

Year 3

The final year focuses heavily on the Smart Factory concept that uses advanced analytics, where Big Data is transformed into meaningful information which optimises the manufacturing process. Students will learn to use Cloud Computing Services to store and analyse acquired actionable data, which can be visually fed back to a machine operator’s console with system parameter changes or real-time control changes made to the automated production line improving the manufacturing process. The final year 60 credit project is a multidisciplinary project that requires the student to apply the topics taught throughout the course and the techniques of processing acquired data in making informed changes to the manufacturing processes. Each student will have a detailed specification for their aspect of the project but will need to work with the other members of the design team to ensure each contribution will seamlessly integrate to fulfil the overall functionality of the machine.

Teaching

Students will be encouraged to contribute in interdisciplinary teams to identify and solve complex engineering or applied real-world problems, beginning with local challenges in the early stages of the course and climbing towards global challenges and a capstone project. The Applied Engineering curriculum is co-designed with industry to ensure students leave with the appropriate skills and knowledge required in the workplace.

The course supports the identity and aspirations of groups of learners who are seeking to learn and explore engineering from an applied perspective related to the modern manufacturing industry.

Assessment

What is novel about this course is that the approach in the delivery is by doing. The course is practically biased assessed through coursework assignments, no examinations. This is due to the subjects’ practical nature, and the skill sets required in our graduates, by the industry.

Zobacz więcej na stronie uniwersytetu >>

Wiza studencka do Wielkiej Brytanii

Aby studiować w Wielkiej Brytanii potrzebujesz wizy studenckiej. Aby złożyć wniosek o taką wizę studencką musisz zdjać certyfikat językowy na poziomie B2.

Uważaj! Do celów wizowych musisz wybrać wyłącznie egzamin w wesji Secure English Language Test (SELT) UKVI .

Co to jest test SELT UK VI registration? Przeczytaj więcej o testach SELT UKVI >>