Course overview

We aim to produce graduates with the versatility and depth of understanding to deal with new and unusual challenges in mechanical engineering, alongside the necessary imagination and creativity to innovate.

- In our ever-changing world, mechanical engineers develop new and differing uses for technologies and materials, in order to improve the mechanical operation of equipment and devices used in anything from food and oil production to international construction projects or the design of toys.

- Ranked 3rd in the UK for the study of Mechanical Engineering (Guardian University Guide 2020), our professionally accredited course gives you the opportunity to qualify first at bachelor and, if you choose to continue, to master’s degree level.

- The course meets the educational requirements of the UK Standard for Professional Engineering Competence (UK-SPEC), which sets out the competence and commitment required for registration, so that upon successful completion, you can practice as a Chartered Engineer (CEng).

Why you should study this course

Mechanical Engineering is the basis for many of the engineering disciplines, including the automotive, aerospace, marine and medical sectors.

- This course is designed to give graduates the opportunity to equip themselves with relevant, up-to-date skills and knowledge necessary to work as a mechanical engineer in a broad variety of businesses, including engineering management, research, engineering design, development and consultancy.

- You will have the opportunity to participate in field trips abroad, which have recently included trips to Poland, Bulgaria, China, Belgium and the USA*. A dedicated industrial placement tutor can help you with your applications for placements and support you if you choose to spend a year in industry*. Past placements have included roles in Aston Martin Lagonda, Babcock International Group, Cummins, GE-Aviation and GKN.

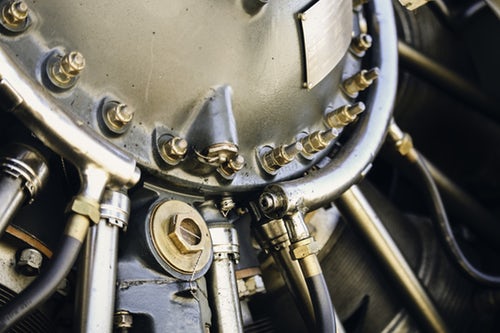

- You will have access to modern facilities in our High Performance Engineering Centre (HPEC). HPEC houses specialist facilities such as a 20% scale model wind tunnel, composites lab, metrology lab, four-pot shaker rig, flow lab, AVL engine test cell, automotive workshop, fatigue and tensile testing (Instron), a full size Harrier Jet, three further simulators, civil engineering specialist testing equipment, a range of CNC machinery and a laser workshop.

What you’ll study

We aim to produce graduates with the versatility and depth of understanding to deal with new and unusual challenges in mechanical engineering, alongside the necessary imagination and creativity to innovate.

The undergraduate degree will provide you with the opportunity to develop essential knowledge and skills in science, commerce, design, manufacturing and management to help prepare you for a career across a broad range of industries with, for example, major equipment manufacturers, design consultancies or supply-chain companies.

As the course progresses, your learning will become more specialised, for example, examining instrumentation and control in Year Two, then thermodynamics and fluid mechanics in Year Three. You will also be able to tailor your course to suit your interests and career aspirations, choosing from a range of optional modules in subjects like finite element analysis or control systems engineering.

At master’s level, we will provide you with the opportunity to deepen your knowledge and understanding of the core subjects involved in the application of science, processes, materials, design and management to enable you to solve problems of increasing complexity. You will have the option to progress to a MEng following successful completion of Year Two (subject to meeting specific grading criteria).

How you’ll learn

Our innovative ‘Activity-Led Learning’ (ALL) approach means you will be given opportunities to work with staff on real-world problems from industry (subject to availability), commerce and research groups, as you would in professional practice. This provides you with an opportunity to develop professional skills at the same time as learning the technical content of your degree. Practical project work may, for example, involve manufacturing prototypes with 3D-printing, reverse engineering of current and past products to produce 3d scanning to create engineering data and geometry to create design models, which can then be used through CAM software to generate CNC machining programs, ready to produce physical products.

Actual teaching contact hours will vary depending on the level of study and the requirements of a particular semester. In a typical week your contact hours will be divided amongst:

- Lectures with associated practice, laboratory, workshop exercises and tutorials

- Problem-based learning in groups with tutor or industrial mentor support

- Group learning

- Formative modelling exercises

- Independent research of library resources, the internet and engineering companies

In addition, you will be expected to undertake significant self-directed study each week, approximately 16-20 hours depending on the demands of individual modules. The number of contact hours may vary from semester to semester, however, on average, it is likely to be around 15 contact hours per week in the first and second year dropping to around 14 contact hours per week in the third and final year as you become a more independent learner.

Assessment

This course will be assessed using a variety of methods which could vary depending upon the module. Assessment methods may include coursework, tests, essays, formal examinations, practical or project work, group work and presentations and posters.

The Coventry University Group assessment strategy ensures that our courses are fairly assessed and allows us to monitor student progression towards the achieving the intended learning outcomes.

Job ready

Upon successful completion, you will be able to:

- Demonstrate advanced knowledge and understanding of: the function, materials, manufacture and assembly of a wide range of engineering products; the principles of engineering science and mathematics and their application and capability in defining and proving the performance of innovative engineering products; aspects of innovative mechanical design, including the design process, design standards and codes, selection of materials and methods of manufacture, and design tools for optimised performance, reliability, weight, cost and sustainability.

- Develop and test strategies for engineering products involving appropriate instrumentation, experimental methods, and data analysis techniques.

- Manage people, processes and engineering projects to promote the commercial success of an engineering enterprise.

- Model and analyse innovative engineering systems using appropriate engineering science and mathematical analysis techniques, such as analysis of aerodynamics, thermodynamic cycles, control systems, stress and dynamics.

- Synthesise solutions to innovative engineering design problems.

- Select appropriate instrumentation for the functional design of innovative engineering products and systems and to support development and test work.

- Search for, and evaluate information sources to identify information essential to solving engineering problems.

- Use test equipment and machines specific to your course, which may include 20% scale model wind tunnel, composites lab, metrology lab, four-pot shaker rig, flow lab, AVL engine test cell, automotive workshop, fatigue and tensile testing (Instron), Modal analysis hardware and software, for experimental work to support product development.

- Use commercial software specific to your course in the solution of engineering problems, which may include noise and vibration, aerodynamic drag and lift and stress analysis.

- Communicate graphically the design of a component or system through sketches, CAD etc.

International experience opportunities

The university is committed to providing a global educational experience and we provide opportunities to participate in a number of collaborative projects and field trips*.

Recent first year students have visited the Warsaw University of Technology in Poland to undertake workshop and computer aided manufacturing skills in an overseas environment. Others have taken part in a collaborative project developing universal healthcare solutions working with the University’s Occupational Therapy students alongside six other institutions from around Europe, participating in international innovation and creativity programmes in Bulgaria (including Ruse) and Hasselt, Belgium.

Further overseas field trips have previously included: test work at the GM proving ground; a tour of the Ford F150 factory in Detroit, USA; a tour of Hirata, a Japanese Tier 1 automotive supplier for Ford, Chrysler and GM; participation on a certificated training course with Altair on Inspire; and visits to Mahle Powertrain, the University of Michigan and Chrysler Building.

We also encourage you to undertake a placement year or study year abroad* after your second year of study. Previously students have been placed in Damen Shipyards in the Netherlands, CERN in Switzerland and Bertrandt in Germany.

Zobacz więcej na stronie uniwersytetu >>

Wiza studencka do Wielkiej Brytanii

Aby studiować w Wielkiej Brytanii potrzebujesz wizy studenckiej. Aby złożyć wniosek o taką wizę studencką musisz zdjać certyfikat językowy na poziomie B2.

Uważaj! Do celów wizowych musisz wybrać wyłącznie egzamin w wesji Secure English Language Test (SELT) UKVI .

Co to jest test SELT UK VI registration? Przeczytaj więcej o testach SELT UKVI >>